Introduction

Whether stainless steel engraving and laser etching aluminium are treated as art or technological expressions, they combine innovative technology with the practice of timeless craftsmanship in a product. Stainless steel engraving can be a way to give more finesse and beauty to your designs. A perfectly etched work of art is the desired outcome because some impression makes calls for precision.

The engraving on stainless steel not only looks elegant but is also a medium for permanent and lasting impressions. Stainless steel is a material very commonly used for plaques, signage, and any other custom design ventures because it is strong and does not react. Since engraving leaves a permanent mark that will never fade away, it is a perfect method of engraving intricate designs that will have to wither over time.

Stainless steel engraving gives you sophistication and durability in your work to let it resonate with the crowd.

Advantages of Laser Etching Aluminium

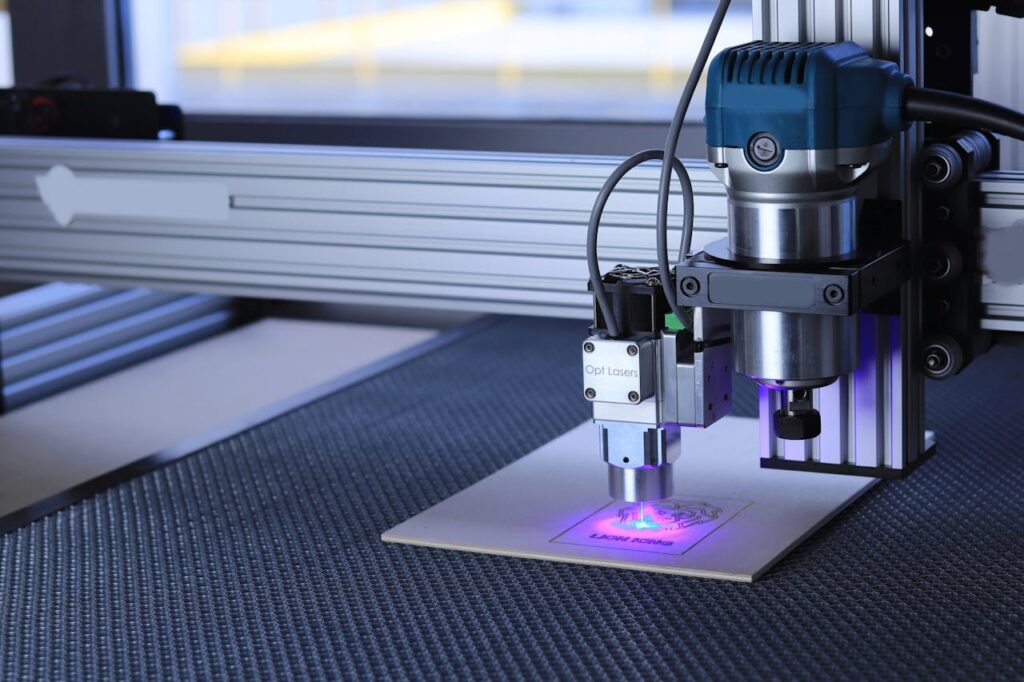

Where engraving steel offers permanence, laser etching aluminium has precision and speed that cannot be compared. This process is suited for manufacturing industries, as the exactness required can only be achieved through such a method. The laser etching provides crisp and clean lines, hence ideal for logos, intricate designs, and a customized art piece.

This technique, while making it look more beautiful, will improve your workflow to get quicker turnarounds with the highest standards.

Actionable Tips for Better Work

Use a Combination of Techniques

On large projects like signage and plaques, you can use stainless steel engraving; laser etching aluminium could add all the small parts and details.

Texture Mix

Use polished and matte finishes and combine them to create contrast and depth in your designs on stainless steel.

Personalization with Precision

Provide custom engraving and etching services for your customers. That way, they will have something that can be personal to them.

Conclusion:

Whether it is with members of the public or decision-makers related to 3D printing and fabrication, your development of such techniques will be what sets your work apart. Do not be afraid to start small, experiment, and let precision and impact through your designs say it all.